IoT in Healthcare Use Cases eBook

Download Your Free IoT in Healthcare Use Cases eBook

Read More

The landscape of manufacturing is evolving. With increased competition and narrower profit margins, manufacturers must adapt to survive. The traditional focus on hardware is no longer sufficient, requiring a strategic shift towards software-driven solutions and service-oriented models.

In this article, we delve into the world of IoT-powered aftermarket services. What are they? Why are they needed? And how can organisations leverage them to drive revenue and boost customer retention and loyalty?

Traditionally, aftermarket services for industrial equipment revolved around reactive measures, addressing issues only once they arose. This keeps the customer's costs low initially, but they can skyrocket once a part fails. Maintenance or replacement costs often pale in comparison to the cost of downtime that equipment failure can cause.

According to the latest research from IoT Analytics, the median cost of unplanned downtime across 11 industries was approximately $125,000 per hour. With risks that high, customers will pay what they have to reduce them, providing equipment manufacturers with a golden opportunity.

For a long time, the solution has been preventive maintenance, where maintenance is performed according to a schedule determined by the manufacturer. The premise is that servicing equipment regularly prevents failures.

Unfortunately, preventive maintenance is disruptive. It requires the equipment to be shut down (as well as any production line or process that requires said equipment), possibly unnecessarily. It may also be ineffective – there is no guarantee that a failure won't occur between maintenance visits.

With the advent of IoT, OEMs now have an opportunity to provide customers with proactive services that reduce both downtime and overall maintenance costs. Condition monitoring using real-time telemetry data powered by IoT enables predictive maintenance.

Embedded IoT sensors can measure things like temperature, vibration, pressure, flow rate, or gas and chemical levels. Manufacturers can use these wireless IoT sensors to monitor commissioned equipment from afar. Trends in the data indicate when a part is beginning to fail, allowing maintenance to be scheduled when needed, causing minimal disruption to the customer.

Predictive maintenance did not emerge with IoT - engineers have been performing this manually for years. But IoT has undoubtedly caused a paradigm shift. The market is currently valued at $5.5 billion, with a projected CAGR of 17% to 2028.

According to McKinsey, predictive maintenance can increase production line availability by up to 15% and reduce maintenance costs by up to 25%. These outcomes represent significant cost savings and increased capacity for customers.

Research shows that in certain sectors, aftermarket lifetime value (total aftermarket revenue as a percentage of the product’s initial sales price) can match that of the original product.

So, as competition for new sales intensifies and profit margins narrow, aftermarket services emerge as a valuable source of revenue. Of course, with a lucrative market comes competition – in this case, from third-party parts and service organisations. Thankfully, IoT-enabled aftermarket services can help on both fronts.

The benefit is two-fold. Manufacturers gain a significant new source of revenue while taking ownership of the customer relationship. Customers get a service that delivers considerable ROI and builds loyalty to the brand. Condition-based or predictive maintenance is a value-added service that sets the OEM's offering apart from third-party aftermarket vendors.

The evolving market offers manufacturers and service providers a clear dichotomy: embrace a flexible, forward-thinking experience that disrupts the competition or risk losing out to agile market entrants seizing the digital opportunity.

In the next section, we'll look at the common use cases for IoT-enabled aftermarket services.

Before the advent of networked sensors, condition monitoring involved a technician taking measurements by hand, usually every month. The data was transferred to a database, stored and reviewed to detect potential problems.

IoT-enabled condition monitoring uses an array of sensors strategically placed on machinery. Accelerometers and vibration sensors capture mechanical vibrations, thermocouples monitor temperature variations, and pressure transducers measure fluid pressures. IoT-enabled cameras and microphones can also be deployed for visual and auditory assessments.

Data from these sensors are transmitted through communication protocols like MQTT (Message Queuing Telemetry Transport) or CoAP (Constrained Application Protocol). This ensures efficient and lightweight communication between devices and the central monitoring system.

Predictive maintenance involves analysing the data acquired during condition monitoring and making decisions based on that data.

Example 1: The IoT platform automatically alerts the vendor or the customer once a metric (e.g. vibration) has exceeded a certain threshold.

Example 2: When a temperature sensor exceeds a safe threshold, the platform alerts the customer via SMS and automatically reduces power to prevent further overheating.

Example 3: An AI model running on the IoT platform continuously monitors the data to detect trends and schedules maintenance once it detects that equipment is beginning to wear.

Predictive maintenance not only enhances customer productivity but also slashes long-term maintenance costs. This, in turn, strengthens the vendor-customer relationship, boosting customer retention and fostering brand loyalty.

Simultaneously, the vendor benefits from increased service revenue and differentiates itself from the competition by providing quality products and premium services. Stock control is also improved—understanding which parts are needed and when prevents delays caused by out-of-stock parts and reduces waste from overstocking.

Product development can benefit greatly from the data acquired during condition monitoring and predictive maintenance. In particular, manufacturers can gain insights into how their customers are using their products and, in turn, improve quality control.

Monitoring multiple metrics makes it much easier to identify the root cause of a single failure. Monitoring an entire fleet of machines in the field allows trends to be identified. Parts or mechanisms prone to failure can be redesigned or upgraded, thereby increasing reliability and reducing parts costs.

Equipment as a Service (EaaS) is a business model that transforms traditional capital-intensive equipment ownership into a service-oriented subscription. Instead of purchasing and owning equipment outright, users pay for access to the equipment and associated services on a subscription basis. The core of EaaS lies in the ability to leverage IoT connectivity, transforming equipment into intelligent, data-generating assets.

From a user perspective, EaaS presents a shift from capital expenditure to a more flexible, subscription-based model. Businesses can access state-of-the-art equipment without the burden of ownership, aligning costs with actual usage. This fosters financial flexibility and ensures access to the latest technological advancements.

For businesses, EaaS represents a strategic move towards sustainable and cost-effective operations, while for consumers, it opens doors to cutting-edge technologies without the traditional barriers of ownership.

At Davra, we've helped numerous organisations get started on their IoT journey. Below, we cover the basic steps that will take you from IoT-zero to IoT-hero.

The first step is sensors - you need to collect data. There are many vendors nowadays producing wireless IoT sensors. For example, Preddio Technologies produces IoT sensors and gateways for industrial environments that can be installed on a range of equipment in less than ten minutes.

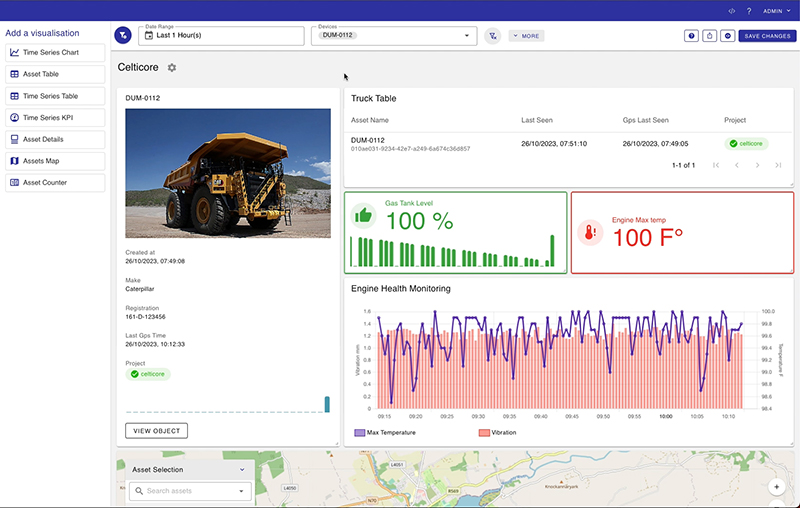

Once you can collect data about your equipment, you need somewhere to send it, analyse it, and store it. This is where an Industrial IoT platform comes in.

An IoT platform will provide all the tools to build, deploy, and manage enterprise-grade IoT applications. This includes device and data management, analytics, and security capabilities. A good IoT platform will also allow you to integrate with any existing ecosystem you have, such as ERP, SCADA, etc. Also known as an Application Enablement Platform (AEP), an IoT platform will get you up and running quickly.

Freeware options are available, and while these can be a great way to test and prototype a solution, they do not have the reliability, scalability, or flexibility needed for industrial solutions. You may end up having to start all over again after creating a prototype on a free IoT platform because you have been locked into certain device types, vendors, or communication protocols. Ultimately, starting with an industrial IoT platform from the beginning will save you time and money.

Once you're collecting and onboarding data, you need to decide what you're going to do with it. This is where Analytics comes in. The term “Analytics” covers everything from a simple line chart to artificial intelligence and is where many will see the value in IoT. I would suggest starting simple and building up to more complex systems over time.

Start by creating a dashboard to see how your equipment is tracking in real time. To add a layer of automation, use the Rules Engine to create a rule that monitors certain metrics in the background. Once a value exceeds a certain threshold, the rules engine will detect it. An alert can be raised on the dashboard, or an SMS message sent to certain individuals, e.g. a site manager.

Get fancy by training a machine learning or AI model on your data to learn what “normal” looks like. Then, create rules about what it should do when something deviates. Combine multiple sensor data sets to get a holistic view of the equipment. This can provide deep insights into why problems arise and may point to ways to improve the design to prevent them.

Finally, create an application for your customers. They want to know what state their equipment is in and when they need to schedule downtime. Simplify all that data into a stunning UI that tells them exactly what they want to know. By preventing breakdowns and outages, you will save your customers time and money, and they will love you for it.

The industrial landscape is changing, but manufacturers can differentiate themselves by embracing IoT. The value proposition of IoT-enabled services is clear—reduced downtime and maintenance costs and improved customer satisfaction.

By leveraging real-time telemetry data, manufacturers can stay competitive and seize a significant source of new revenue while solidifying their customer relationships. Those who do so are advised to invest in an IoT platform rather than building a solution from scratch. The result is not just a faster entry into the market but a strategic advantage over competitors still mired in traditional approaches.

The choice is clear: OEMs must offer a progressive, technology-focused customer experience or face being pushed out by the competition. After all, sourcing new revenue from existing customers is a much smarter game than constantly chasing new ones.

Download Your Free IoT in Healthcare Use Cases eBook

Davra IoT is the only Industrial IoT Platform Available on AWS Marketplace

Read MoreThe Collaboration of Humans & Robots Has Created The Cobot

Read More