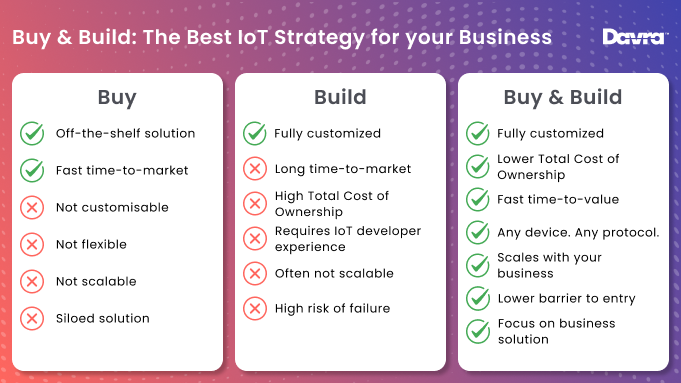

Today’s changing business landscape compels OEMs and machinery manufacturers to look to the Industrial Internet of Things (IIoT) for new customer-oriented, revenue-boosting business models. As companies explore the many IIoT solutions, a crucial question arises: Should they buy pre-existing solutions, build their own from scratch, or embrace a hybrid approach? This article discusses the “Buy” and “Build” approaches, outlining their advantages and disadvantages. We suggest that the most successful IoT organisations are adopting a different strategy, the “Buy and Build” model.

Executive Summary

- Industrial OEM and machinery manufacturers are looking to the Industrial Internet of Things (IIoT) for customer-oriented, revenue-boosting business models.

- When these companies begin their IoT journey, they often struggle over purchasing a pre-made solution or creating one themselves – the so-called Build vs. Buy dilemma.

- Each approach comes with notable disadvantages, contributing to the fact that three-quarters of businesses view their IoT projects as unsuccessful.

- Savvy organisations that adopt a “Buy and Build” approach to their IoT projects experience the benefits of both strategies without encountering these drawbacks.

- The Buy and Build strategy involves investing in an Industrial IoT platform that provides the tools to create a customised IoT solution. With Build and Buy, organisations get a custom IoT solution much faster than it would take to build from scratch.

- Buy and Build reduces project costs by 55% and go-to-market time by 72% on average while providing a customised solution that scales with the business.

Why you need an Industrial IoT strategy?

Industrial IoT is transforming industries with its ability to drive efficiencies, cut costs, create new revenue streams, and promote sustainable practices. Well-implemented systems allow original equipment manufacturers to visualise, monitor, and manage remote assets in real-time.

Research (opens new window) by McKinsey shows that the revenue share for industrial equipment and machinery companies is shifting away from new product sales and toward software and after-market services. IIoT will be central to this change.

Many forward-looking enterprise organisations have successfully implemented IoT strategies and boast IIoT applications across various industrial sectors, harnessing data, connectivity, automation, and analytics capabilities to optimise operations and yield advantages for their businesses.

Industrial IoT Use Cases

These six IIoT use cases are delivering tangible benefits to companies.

Predictive Analytics – Using data analysis and AI to predict future outcomes, enabling proactive decision-making and preventive actions.

Condition Monitoring – Continuous tracking of machinery and equipment health to detect faults early, prevent costly breakdowns and optimise maintenance.

Asset Tracking & Management – Real-time location monitoring and management of physical assets, such as equipment, vehicles, inventory, or even people.

Connected Industrial Assets – Connecting equipment, machines, and devices in industrial environments to enhance operations, data sharing, and real-time monitoring.

Sustainability – Embracing eco-friendly practices into business operations to reduce environmental impact and promote long-term viability.

Safety & Risk Management – Identifying, assessing, and mitigating potential risks to business processes, assets, and operations for improved safety and stability. IIoT can contribute to workplace safety by monitoring conditions and providing alerts in hazardous environments. It can also help with regulatory compliance (opens new window) by tracking and documenting processes.

Build vs. Buy

As companies embark on their IoT journey, one of the first questions they ask is whether they should buy a ready-made IoT solution or build their own from scratch. This is the so-called Build vs. Buy dilemma. Below, we will outline the advantages and disadvantages of each of these approaches.

The Buy Model for IoT

Opting for the “Buy” IoT strategy means acquiring an essentially pre-packaged IoT system, offering a quick route to market with an off-the-shelf solution. Typically, companies design these systems to serve a particular function, such as asset monitoring in a factory setting. They perform their advertised functions well and provide an easy and efficient route to market for many. However, this approach has some drawbacks, particularly for enterprise organisations.

Pre-packaged solutions typically do not offer customisation beyond basic cosmetic changes and may not align with your specific needs or business model. These solutions often lack flexibility and may have limited or fixed compatibility with certain IoT technologies, communication protocols, and vendors.

If your business’s IoT use cases expand, you must add new siloed solutions or start from scratch, making the old solution incompatible with your new IoT infrastructure.

Pre-built solutions often fail to meet the rigorous security and compliance standards crucial for most enterprise organisations, for example, ISO 9001:2015, ISO 27001:2017, SOC2, etc. Additionally, such solutions rarely factor scalability into their designs, making them less suitable for large-scale deployments.

"Buy" Summary

- Buying an off-the-shelf IoT solution provides companies with a basic offering and a quick route to market.

- Pre-packaged solutions provide limited customisation options beyond cosmetic changes.

- Limited compatibility may preclude many organisations with existing infrastructure.

- Companies may struggle to scale an off-the-shelf solution beyond a POC or pilot program.

- Organisations in highly regulated sectors may struggle to find solutions that meet compliance requirements.

The Build Model for IoT

Ambitious decision-makers may find building their own in-house IoT solution attractive. The benefits of this approach are straightforward. You get a system that is custom-built from the ground up to suit your needs and solve your pain points. However, the potential pitfalls of this route are many. Chief among these is the acute need for high-level expertise.

Embarking on a journey to build a bespoke IoT solution might seem enticing, but it’s rife with challenges. Alarmingly, 74% of companies (opens new window) view their IoT projects as unsuccessful. Factors contributing to this include extended time-to-market, inadequate expertise, and not understanding the requirements for IoT implementation. Developing an IoT solution from the ground up demands substantial resources and entails significant risks.

In-house IoT projects frequently encounter substantial delays, scope creep, and build-up of technical debt, resulting in extended time-to-market, which can span years. A robust IoT platform necessitates the integration of numerous complex components to function effectively and at scale. As an IoT industry veteran of over a decade, we at Davra can attest to the time and effort required to make these systems work.

Next, scaling a solution may be as difficult as building it. We see this often – companies come to us because they hit scaling challenges after initially promising results with a proof of concept or small-scale deployment. Unfortunately, this only becomes apparent in many cases once the project is too far down the path, making it expensive to correct.

How to successfully execute a “Build” strategy

A successful IoT strategy requires complex and often expensive components. While outstanding freeware options are available (and Davra uses several), freeware does not mean zero cost. Companies must still integrate, update, and maintain these systems throughout the product life cycle, resulting in substantial long-term overhead costs.

The “Build” IoT business strategy requires extensive expertise to develop a functioning cloud service delivery architecture. Unless this technical expertise is a part of your core business, you’ll likely need to set up a new function within the business.

An IoT function typically requires the following expertise: software architects, big data architects, information security professionals, site reliability teams, and monitoring infrastructure. Unfortunately, the skill sets these professionals offer can be expensive. You will also need significant hands-on expertise in operations, change control, and security controls.

As a result of all of these factors, the total cost of ownership (TCO) for a homegrown IoT solution can often exceed the initial budget for the project. As a result, many companies either abandon the project, undergo an expensive migration to a platform, or face ever-increasing costs.

“Build” Summary

- Building an IoT solution in-house allows organisations to create a fully customised solution suited to their business.

- Companies must properly scope and resource an IoT project or risk the project failing.

- When planning an in-house IoT project, organisations should consider both the upfront investment and the support and maintenance over time (total cost of ownership).

- Companies need high-level IoT skills and expertise to successfully deliver a “Build” strategy. The organisation must set up a new function in the business if these skills are absent.

- Enterprise organisations that do not build in good scaling practices from the start risk failing when the project leaves the pilot phase.

- Compared to the alternatives, “Build” IoT strategies have the longest time-to-market even when executed well.

- Comparing Buy and Build IoT strategies against Buy AND Build.

The “Buy and Build” IoT Strategy

Both “Buy” and “Build” strategies have significant disadvantages, particularly for enterprises looking to create custom solutions with high ROI and get to market quickly. However, another IoT strategy combines the benefits of both without the drawbacks – Buy and Build.

In the business world, Buy and Build usually refers to buying and expanding a company by leveraging opportunities the previous owner could not exploit. Regarding IoT, Buy and Build means buying an Industrial IoT (IIoT) platform and building your business solution on top. A high-quality platform has essential tools for device integration, system interoperability, cutting-edge analytics, and a flexible application enablement framework.

By leveraging these building blocks, an IIoT platform allows you to focus on addressing a smaller, business-critical problem set that sets you apart from the competition. This approach provides all the benefits of a proven and reliable system while retaining the flexibility to create a tailored solution.

What is an Industrial IoT (IIoT) platform?

An Industrial IoT platform is a comprehensive software framework that facilitates building, deploying, managing, and operating industrial IoT applications and devices within an industrial environment. It is a central hub for collecting, processing, analysing, and visualising data from various sensors, machines, and devices in an industrial setting. Also known as an Application Enablement Platform (AEP), an IIoT platform provides all the necessary tools to build successful IoT solutions without needing to be experts in IoT.

The 8 Pillars of IIoT

A “full-stack” IIoT platform is a comprehensive solution encompassing eight essential pillars to enable seamless and efficient industrial operations. These pillars work in tandem to provide a holistic and integrated ecosystem for managing industrial processes and data. Below, we expand on each of these pillars.

Application Enablement – Application Enablement is the foundation of the IIoT platform, allowing users to create and deploy custom applications and services tailored to specific industrial needs. This pillar offers tools, APIs, and development environments for building applications that interface with IIoT devices and data.

Analytics – Analytics involves processing and analysing the vast amounts of data IoT devices generate. This pillar includes real-time data analytics, predictive analytics, and machine learning tools to extract valuable insights from data, aiding decision-making and optimising operations.

Integrations – Integrations facilitate the seamless integration of IoT data with existing enterprise systems such as ERP (Enterprise Resource Planning) and CRM (Customer Relationship Management). It ensures data flows smoothly between various applications and systems, enabling end-to-end automation and efficiency.

Security – Security is paramount in IIoT to protect critical infrastructure and data. This pillar includes data encryption, authentication mechanisms, access control, and threat detection to safeguard against cyber threats and ensure the confidentiality, integrity, and availability of industrial data and systems.

Join our Mailing List

Join thousands of professionals and get IoT tips to help you transform your business.

Device Management – Device management encompasses the management of IoT devices throughout their lifecycle. This includes provisioning, configuration, monitoring, firmware updates, and remote diagnostics. Effective device management ensures the reliability and performance of connected devices.

Data Management – Data management involves collecting, storing, and organising data generated by industrial devices. It includes data preprocessing, normalisation, and transformation to make the data usable for analytics and decision-making. This pillar ensures data accuracy, quality, and availability.

Digital Twins – Digital Twins are virtual replicas of physical assets or processes. This pillar facilitates the creation and management of digital twins, allowing organisations to simulate and analyse real-world scenarios, optimise operations, and predict maintenance needs accurately.

Edge AI – Edge AI brings intelligence and decision-making capabilities closer to the data source, reducing latency and improving real-time decision-making. This pillar involves deploying AI and machine learning algorithms on edge devices, such as sensors and gateways, to process data locally and provide immediate insights.

Industrial equipment and machinery manufacturers should consider a Buy and Build approach for their IoT strategy.

The Benefits of "Buy and Build"

For most organisations, the Buy and Build model provides both a faster route to market and long-term strategic benefits. You get a solid, reliable, and fully scalable system with the flexibility and support you need to stay competitive and grow. Here are some advantages a Buy and Build IoT strategy can provide.

Reduced Total Cost of Ownership (TCO) – By purchasing an existing IoT platform that is custom-built to support your business needs, you can avoid the high costs of developing a solution from scratch. Our research shows that investing in a platform reduces project costs by 55%, to say nothing about the long-term savings.

Faster Time-to-Value – Leveraging a proven and trusted IoT platform allows you to bring your solution to market faster than building it internally. Our data shows that investing in an IIoT platform reduces time-to-market for IoT projects by 72%. This accelerated time-to-market can give you a competitive advantage and help you quickly realise a return on your investment.

Scalability – An IoT platform is designed to scale with your business as it grows. Homegrown solutions may work for initial pilots but can become challenging to scale up to production. Using a platform that can expand alongside your needs ensures long-term success.

Focus on Core Business – We’ve already seen that an IoT solution requires complex elements like device management and security. Buying an IoT platform offloads these challenges, allowing your team to focus on developing and enhancing your core business applications. This streamlines your efforts and improves efficiency.

Long-Term Strategic Benefits – An IIoT platform provides ongoing benefits that increase over time. As your business expands, you can leverage the platform to add new applications, generate additional revenue, and future-proof your IoT roadmap without incurring excessive maintenance and support costs.

Lower barrier to entry – Microservices and Docker containers allow you to develop your applications in familiar programming languages, reducing the need for specialised IoT expertise. This approach empowers your existing team of developers to work on IoT projects efficiently and requires less investment upfront for specific skill sets.

Access to Additional Features – Established IoT platform vendors like Davra have years of experience and a deep understanding of common IoT challenges. We provide valuable insights and solutions to help you overcome hurdles faster. Regular platform updates also give access to new and improved features, enhancing your IoT solution’s capabilities.

Expert Support – Partnering with an experienced IoT platform vendor also includes access to expert support. This can be instrumental in troubleshooting issues, optimising performance, and ensuring the smooth operation of your IoT ecosystem.

The Buy and Build IoT business strategy allows organisations to quickly and cost-effectively implement IoT solutions while benefiting from scalability, reduced complexity, and ongoing support. This approach enables businesses to focus on their core competencies, accelerates time-to-market, and positions them for long-term success in the rapidly evolving IoT landscape.

Conclusions

- Industrial equipment and machinery manufacturers should consider a Buy and Build approach for their IoT strategy.

- Analysis of customer data shows Buy and Build leads to a 72% faster time-to-market compared to building an in-house solution and reduces project costs by 55%.

- By leveraging the features of an IIoT platform, companies can focus on the much smaller problem set, such as addressing the needs of their business.

- A Buy and Build approach lowers the barrier to entry to IoT, enabling smaller organisations and those without IoT experience to succeed.

- Ready to start your IoT journey or have a solution struggling to scale? Get in touch with a Davra expert today. We can help you assess your options for delivering a new IoT solution or migrating from an existing one.

Ready to start your IoT journey or have a solution struggling to scale? Get in touch with a Davra expert today. We can help you assess your options for delivering a new IoT solution or migrating from an existing one.